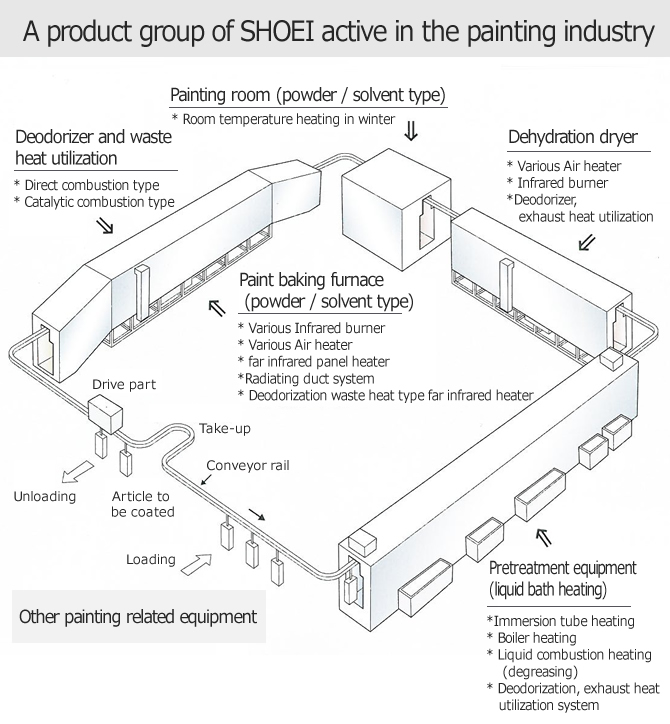

Pre-treatment furnace and liquid heating device (gas combustion type)

Pre-treatment furnace and liquid heating device (gas combustion type)

[ Description ]

Pretreatment furnace and liquid heating device for pretreatment.

Heating of the chemical liquid is performed by "under-fired liquid bath heating", "immersion tube heating"

For hot water washing (hot water) heating, there are liquid heating methods such as "under-fired liquid bath heating", "immersion tube heating" and "submerged combustion burner (efficiency up to 63°C 90%)".

(Supplementary explanation)

Pretreatment is a process for removing foreign substances adhering to and generating on the surface of a workpiece before coating, and improving corrosion resistance and adhesion of the coating film.

Degreasing, de-rusting, coating formation and the like.

Representative steps are degreasing (caustic soda, carbonate soda, etc.) → water wash → rust removal (sulfuric acid, hydrochloric acid etc.) → water wash → chemical treatment (zinc phosphate etc.) → water wash → post-treatment → draining drying.

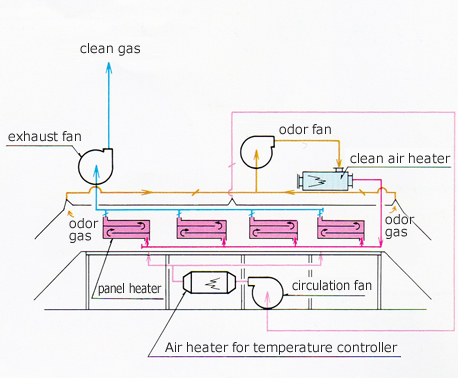

Dehydration dryer

Dehydration dryer

[ Description ]

Dehydration dry has a gas hot air type (direct / indirect) drying furnace and radiation (far infrared / near infrared ray type) drying furnace.

Especially, the radiant tube method using exhaust heat from the drying furnace is economical.

[ Supplementary explanation ]

Dehydration dry is a process of drying the washing water adhering to the object to be coated by pretreatment.

Painting room (powder / solvent type)

Painting room (powder / solvent type)

[ Description ]

In addition to paint booth of solvent paint, gun for powder coating and special booth.

[ Supplementary explanation ]

Especially powder coatings do not use hazardous solvents, and color change is also easy.

Paint baking furnace (QUICK CURING SYSTEM)

Paint baking furnace (QUICK CURING SYSTEM)

Far infrared panel + hot air system ... solvent type

[ Description ]

Compared to the conventional heating method using only hot air, by using "far infrared (electromagnetic wave) and hot air" in combination, heating efficiency will be increased and processing time will be shortened.

Especially when using a hot air duct type far infrared panel, it is also possible to save fuel cost by using waste heat etc. of deodorizer.

[ Supplementary explanation ]

Baking of solvent based paint can be done faster than conventional hot air, effectively burning by combination of hot air treatment and far infrared panel.

Gas large infrared burner + hot air system ... powder system

[ Description ]

Compared with conventional hot air, electric heater, lamp etc., gas large infrared heater (burner) is used in the setting process, it can overwhelmingly heat at high temperature in a short time.

Including waste heat from the infrared burner, it is possible to finish baking at the hot air zone of the second half, and it is possible to bake for 3 minutes.

[ Supplementary explanation ]

Powder paint and water paint can be rapidly heated by combining gas-fired infrared rays and far infrared rays as a preliminary process of hot air, and shortening (compacting) furnace equipment is also possible.

Catalytic radiation panel (Sunkiss thermoreactor) + hot air system...Solvent system / powder system

[ Description ]

Compared with traditional hot air, electric heater, lamp etc., when using the catalyst radiation panel (Sunkiss thermoreactor) in the setting process, it can heat at high temperature in an overwhelmingly short time.

[ Supplementary explanation ]

Sunkiss Thermoreactor can be used regardless of the type of solvent paint, powder paint and water paint.

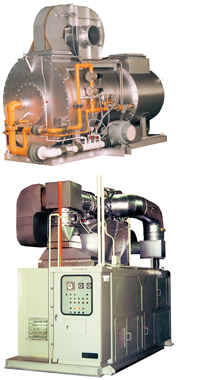

Deodorizer (direct combustion type, catalytic combustion type, thermal storage type) and waste heat utilization system

Deodorizer (direct combustion type, catalytic combustion type, thermal storage type) and waste heat utilization system

[ Description ]

Direct combustion type : Odor is oxidized and decomposed at high temperature.Catalytic Combustion Type : The odor is decomposed by using the oxidizing power of the catalyst.

The direct combustion type or catalytic type deodorizer can utilize heat such as exhaust heat after decomposition of odor by using a heat exchanger for preheating the odor or passing it through a low temperature radiation pipe of a draining furnace.

Heat storage type : The deodorization method is the same as the direct combustion type, but it is an energy saving deodorizing device that recovers waste heat by built-in regenerator.

Other painting related equipment

Other painting related equipment

Ultraviolet curing device

[ Description ]

It is adopted when using UV curable paint.

Continuous color coating line

[ Description ]

It is a line to continuously paint and bake a rolled metal plate.

Hanger firing furnace

[ Description ]

It is an inline furnace that burns paint adhered to a hanger.